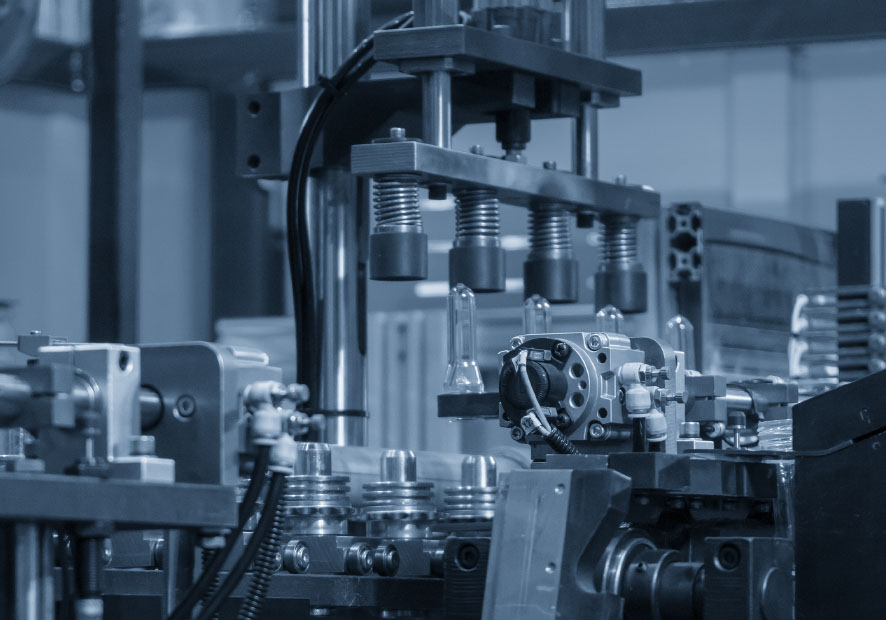

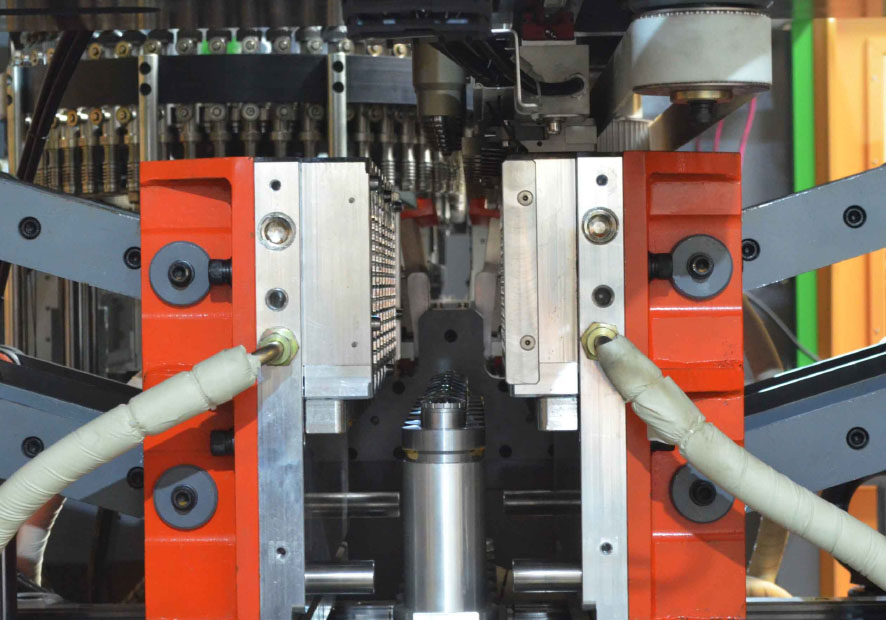

Semi Automatic 2 Cavity 3L Wide Mouth Plastic Red Dates Jar Blow Molding Machine

semi-automatic bottle blowing machine is designed and improved on the basis of a manual bottle blowing machine, meeting CE standards. Controlled by a microcomputer, the technical parameters involved can be more accurately controlled. Easy to operate, safe, only one person is required, and no special training is required. The semi-automatic bottle blowing machine can blow carbonated beverage bottles, mineral water bottles, cosmetics bottles, hot filling bottles, especially oil bottles with handles.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes. It is widely used to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle etc. Beverage bottle, cosmetic bottle, medicine bottle, jar etc.

Category

|

Project |

QA-3L Jar/Wide Mouth |

The Finished Product

|

The Raw Material |

PET |

Volume |

3L |

|

The Theory of Production |

800-1600PCS/H |

|

The Maximum Height |

350MM |

|

The Largest Diameter |

115MM |

|

Template Size

|

Theoretical Output |

360*410MM |

Max Mold Thickness |

220MM |

|

Min Mold Thickness |

90MM |

|

Clamping Force |

10TKN |

|

Open Touch the Trip |

155MM |

|

The Host Power

|

Power |

8KW |

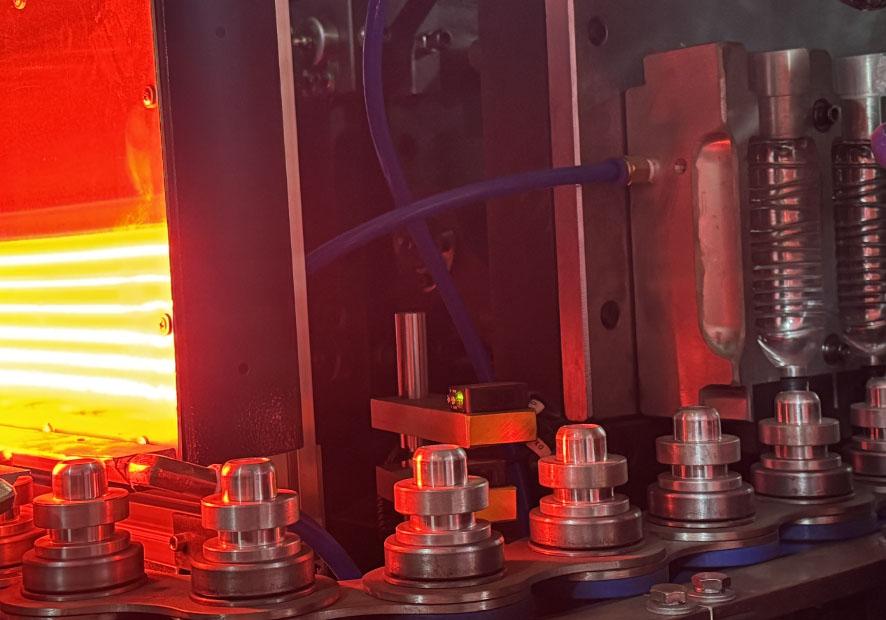

The Oven Power

|

Voltage / Frequency (three-phase) |

380V/50HZ/60HZ |

Size

|

Host |

1720*650*1690MM |

Oven |

1720*585*1370MM |

|

Weight

|

Host |

570KG |

Oven |

260KG |

Four core advantages to help efficient production

High efficiency and stability, excellent production capacity

Energy saving and environmental protection, reducing operation

Stable and durable, low failure rate

Full-process service

Features

01.

Intelligent servo drive system

02.

Highly efficient and energy-saving heating solutions

03.

Intelligent process control systems

04.

Reliable mechanical structure

Frequently Asked Questions

Answer: It depends on the model (single or multi-cavity). Standard machines produce 1,000–5,000 bottles/hour, while high-speed models can reach 10,000+ bottles/hour. We customize solutions based on yo...

Answer: Yes! Our machines support virgin PET and rPET (up to 30–50% recycled content, depending on bottle quality requirements). We optimize heating and blowing for stable performance.

Answer: With our quick mold-change system, switching takes 15–30 minutes (vs. 1–2 hours for traditional machines), minimizing downtime.

Answer: Advanced servo-driven machines save 20–30% energy vs. hydraulic models. For example, a 20-cavity machine consumes ~25–35 kW/h.

Answer: Our machines feature:Precision temperature control (±1°C)Automatic wall thickness adjustmentReal-time defect detection (rejects faulty bottles)

Answer: Regular maintenance includes:Daily: Lubrication, air pressure checksMonthly: Mold cleaning, heater inspectionYearly: Servo motor and hydraulic system overhaul

Answer: Yes! We offer turnkey solutions, including:Preform injection machinesBlow moldersConveyors, labelers, fillersQuality inspection systems

Answer: We provide:1–2 years warranty (core parts)24/7 remote supportOn-site technician dispatch (if needed)

Ordering Process for Our Blow Molding Machines:

| Step | Stage | Description | Key Activities & Deliverables |

|---|---|---|---|

| 1 | Initial Inquiry & Consultation | You contact us to express your needs. | • Submit your requirements (bottle design, output capacity, material). • Our technical team provides initial consultation and machine recommendations. |

| 2 | Technical & Commercial Proposal | We provide a detailed offer based on your needs. | • Receive a formal quotation including machine specifications, price, and delivery terms. • Layout drawing and performance data provided for review. |

| 3 | Proposal Review & Negotiation | We discuss and refine the offer to meet your expectations. | • Clarify technical details and commercial terms (payment, warranty, training). • Adjust the proposal as needed. |

| 4 | Order Confirmation & Contract Signing | The agreement is formalized. | • Sign a sales contract or acknowledge a Proforma Invoice (PI). • Provide an official purchase order (PO) from your company. |

| 5 | Payment (Advance) | You make the initial payment to secure production. | • Pay the first installment (e.g., 30%-50% of the total amount) as per the contract. |

| 6 | Machine Production & Testing | We manufacture and rigorously test your machine. | • We build the machine to your specifications. • A factory acceptance test (FAT) is conducted. You are welcome to witness it. |

| 7 | Final Payment & Shipping Preparation | You clear the balance payment before shipment. | • Settle the remaining balance upon successful FAT and before dispatch. • We prepare all shipping and customs documentation. |

| 8 | Packaging & Shipment | Your machine is securely packed and shipped. | • The machine is crated for safe international or domestic transport. • We arrange shipment and provide tracking details. |

| 9 | Installation & Commissioning | Our engineers assist with setup at your factory. | • Our technicians arrive at your site (if included in the contract). • The machine is installed, calibrated, and tested with your materials. |

| 10 | Training & Final Acceptance | Your operators are trained on the machine. | • Comprehensive hands-on training is provided. • Perform Site Acceptance Test (SAT) and sign the final acceptance certificate. |

| 11 | After-Sales Support | Our ongoing support begins. | • Warranty period activation. • Lifetime technical support and supply of spare parts. |

Contact us

- Taizhou Pinsheng Machinery Co., Ltd.

- Niqiaojin Village, Xicheng Street, Huangyan District, Taizhou City, Zhejiang Province

- 手机: 008613058799699

- Mail: tzpinsheng@163.com