Help you create efficient and reliable bottle blowing production solutions

Good reasons to work with us

As a professional blow molding machine manufacturer, we are committed to providing customers with high-performance, high-stability, cost-effective blow molding equipment and comprehensive service support.

Whether you are a beverage, edible oil, daily chemical product or pharmaceutical packaging company, working with us will bring significant advantages to your production:

Whether you are a beverage, edible oil, daily chemical product or pharmaceutical packaging company, working with us will bring significant advantages to your production:

01.

Industry-leading technology and innovation

With 15 years of industry experience, we use internationally advanced bottle blowing technology (such as fully electric/hydraulic systems). Our equipment accuracy reaches ±0.1mm, increasing production efficiency by more than 30%, helping you seize market opportunities.

01.

Cost-effective customized solutions

We offer flexible configurations from single-cavity to multi-cavity modules, supporting a variety of materials such as PET, PP, and HDPE. We can customize solutions based on your production capacity needs and reduce single-bottle production costs by 20%-35%.

02.

Excellent energy efficiency and environmental performance

The equipment is equipped with intelligent energy-saving systems (such as heat recovery and low-gas consumption technology), which reduces energy consumption by 25% compared to traditional models. It complies with EU CE/US FDA standards and contributes to green production.

03.

Stable and reliable equipment durability

Core components are made of German/Japanese components and precision processing technology, with a mean time between failures (MTBF) exceeding 10,000 hours, extending the service life by 50% and reducing downtime losses.

05.

Full-cycle service guarantee

We provide 24-hour global technical support, free operation training, lifelong maintenance, and spare parts supply covering more than 100 countries and regions to ensure worry-free production.

06.

Mature cases and brand endorsement

We have provided equipment to many internationally renowned beverage/daily chemical companies (including leading customers in the industry), with a customer repurchase rate of over 85%, which is doubly verified by quality and reputation.

07.

Quick mold change to improve production efficiency

Modular design shortens mold change time to 15 minutes, reduces production switching time, and improves equipment utilization. Adapts to different bottle shapes (round bottles, square bottles, special-shaped bottles, etc.)

08.

Strict quality control to ensure equipment reliability

Each device undergoes 72 hours of continuous testing before leaving the factory and complies with international certifications such as CE and FDA, ensuring quality.

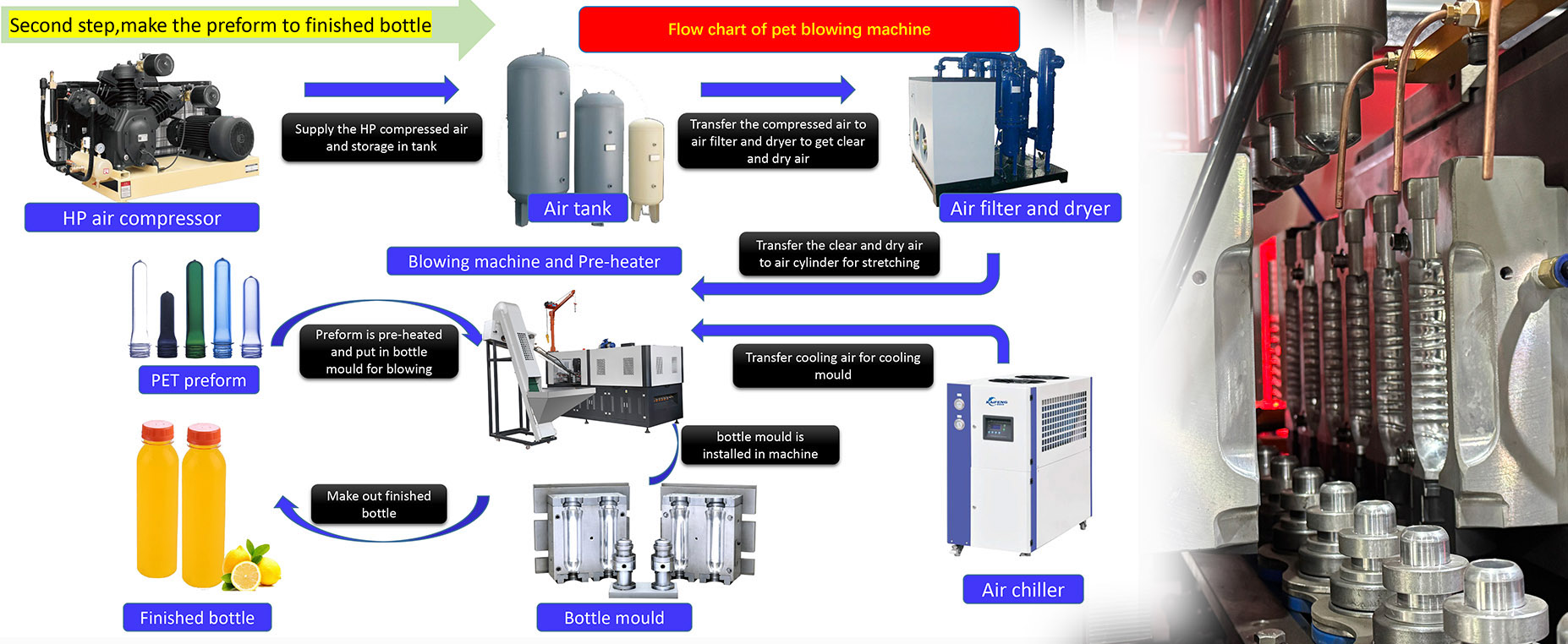

Detailed explanation of the production process of bottle blowing machine

The bottle blowing machine is the core equipment for producing PET, PP, HDPE and other plastic bottles. Its production process mainly includes key steps such as preform heating, pre-blowing and stretching, high-pressure blow molding, cooling and shaping. The following is a detailed description of the process flow