Fully Automatic vs. Semi-Automatic Blow Molding Machines: A Comprehensive Comparison

In the world of PET bottle manufacturing, the choice between a fully automatic and a semi-automatic blow molding machine is one of the most critical decisions a producer will make. This choice fundamentally impacts production capacity, labor costs, operational complexity, and the overall business model. Understanding the key differences is essential for selecting the right technology for your specific needs.

At a Glance: Core Difference

Semi-Automatic Machines: Require significant human intervention for key steps. An operator must manually load preforms into the machine and unload finished bottles. The blowing process itself is automated.

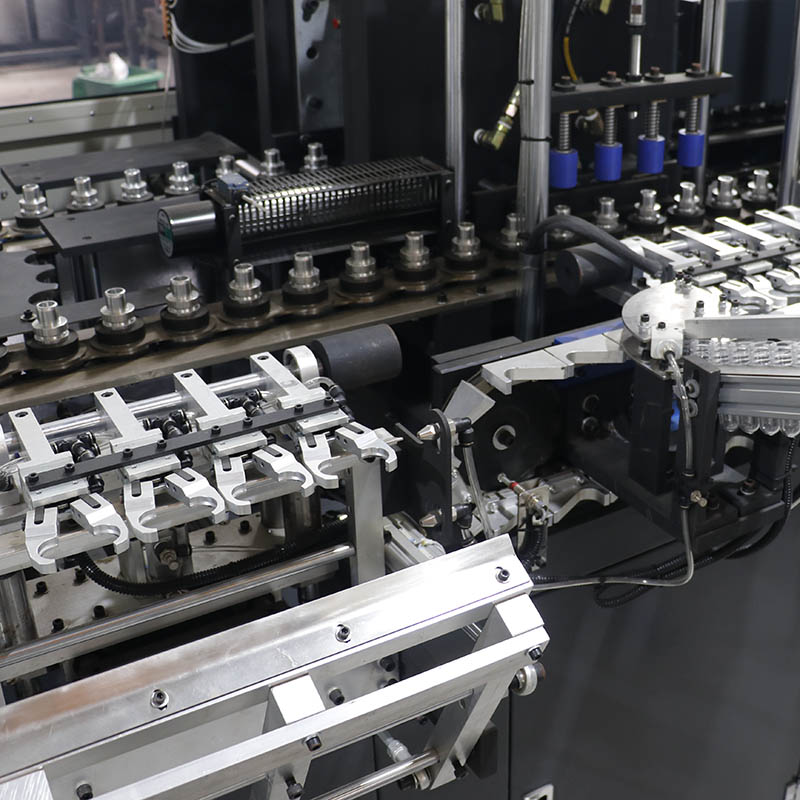

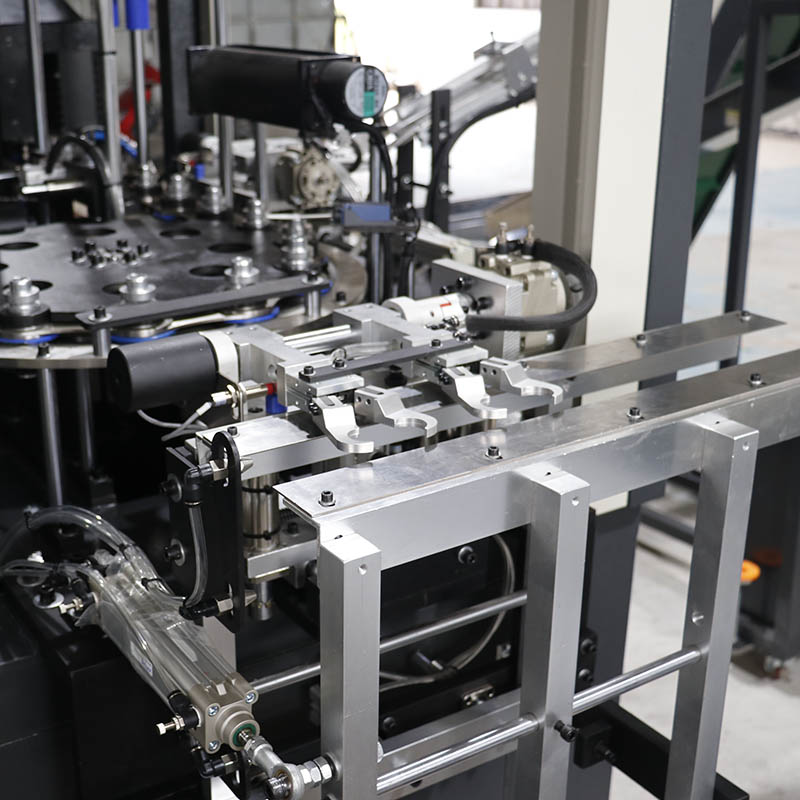

Fully Automatic Machines: Are integrated, robotic systems. They automatically load preforms, execute the blow molding process, eject finished bottles, and handle them via conveyors for downstream operations like labeling and packing. Human intervention is minimal, primarily for supervision and maintenance.

Detailed Comparison

| Feature | Semi-Automatic Blow Molding Machine | Fully Automatic Blow Molding Machine |

|---|---|---|

| Operation & Labor | High manual involvement. Requires 1-2 operators per machine to load preforms and unload bottles continuously. | Minimal manual involvement. Fully automated from preform loading to bottle ejection. One operator can supervise multiple lines. |

| Production Capacity | Low to Medium. Typically 800 - 2,500 bottles per hour (BPH) per machine. Limited by operator speed and endurance. | Very High. Ranges from 4,000 to over 50,000 BPH for multi-cavity lines. Designed for continuous, 24/7 operation. |

| Footprint & Layout | Compact. The machine itself is smaller, but requires clear space for operators to work around it. | Large. Requires a significant integrated layout with automatic preform elevators, conveyors, and silos for material handling. |

| Energy Efficiency | Lower. Energy is used intermittently as the machine often idles between cycles waiting for operator action. | Higher. Optimized for continuous running, leading to better energy utilization per bottle produced. |

| Initial Investment | Low. Significantly cheaper to purchase and install. Lower barrier to entry for small businesses. | Very High. Substantial capital expenditure for the machine, auxiliary equipment (air compressors, chillers), and installation. |

| Flexibility & Changeover | High. Easy and quick to switch between different bottle designs and preforms. Ideal for short, custom runs. | Low to Medium. Changeovers are more complex and time-consuming, involving robotic reprogramming and mold adjustments. Best for long runs of a single design. |

| Consistency & Quality | Variable. Prone to human error and fatigue. Bottle quality (e.g., wall thickness, clarity) can vary between shifts or operators. | Extremely Consistent. Precisely repeatable process ensures every bottle is identical, guaranteeing high and uniform quality. |

| Hygiene & Contamination Risk | Higher. Direct human handling of preforms and bottles increases the risk of contamination. | Very Low. Closed or minimally handled system is ideal for food, beverage, and pharmaceutical applications where hygiene is paramount. |

| Skill Level Required | Lower. Operators require basic training to load and unload. Technical knowledge is needed only for setup and troubleshooting. | Higher. Requires skilled technicians and engineers for programming, maintenance, and complex troubleshooting. |

Advantages and Disadvantages

Semi-Automatic Machines

Pros:

Low initial investment cost.

High flexibility for short production runs and frequent product changes.

Simpler to maintain and repair.

Lower technical skill requirement for operators.

Cons:

High and ongoing labor costs.

Limited production output and scalability.

Inconsistent product quality due to manual operation.

Not suitable for high-hygiene environments.

Physically demanding and monotonous work for operators.

Fully Automatic Machines

Pros:

Very high production output and efficiency.

Dramatically lower labor costs per bottle.

Exceptional and consistent product quality.

Superior hygiene and reduced contamination risk.

Better energy efficiency during continuous operation.

Capable of true lights-out (unmanned) manufacturing.

Cons:

Extremely high initial capital investment.

Inflexible; poor suited for small, custom jobs.

Complex maintenance requires highly skilled staff.

Significant factory space and infrastructure required.