Your Partner for Efficient, Precise, and Innovative Plastic Packaging Solutions

In the fast-paced world of consumer goods, the packaging is more than just a container; it's a critical component of brand identity, product protection, and supply chain efficiency. At the heart of this ecosystem lies the modern, fully automatic blow molding plant—a marvel of engineering that transforms raw PET material into perfect plastic bottles with unparalleled speed, consistency, and ingenuity. This is not merely manufacturing; it is the delivery of comprehensive packaging solutions built on the pillars of efficiency, precision, and innovation.

1. Unmatched Efficiency: The Engine of Productivity

A fully automatic plant is designed for one primary goal: maximizing output while minimizing waste and cost.

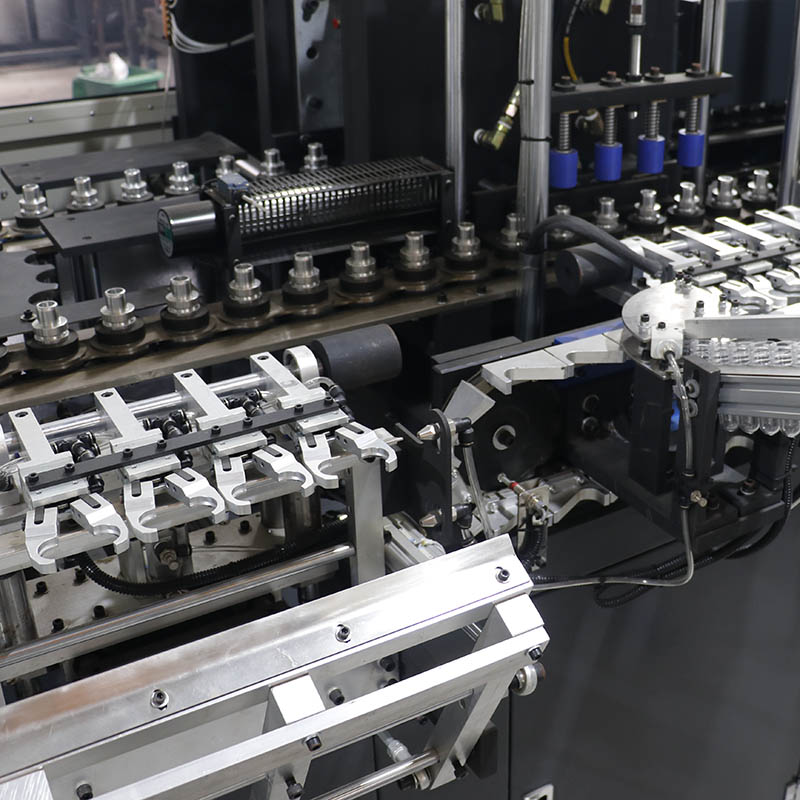

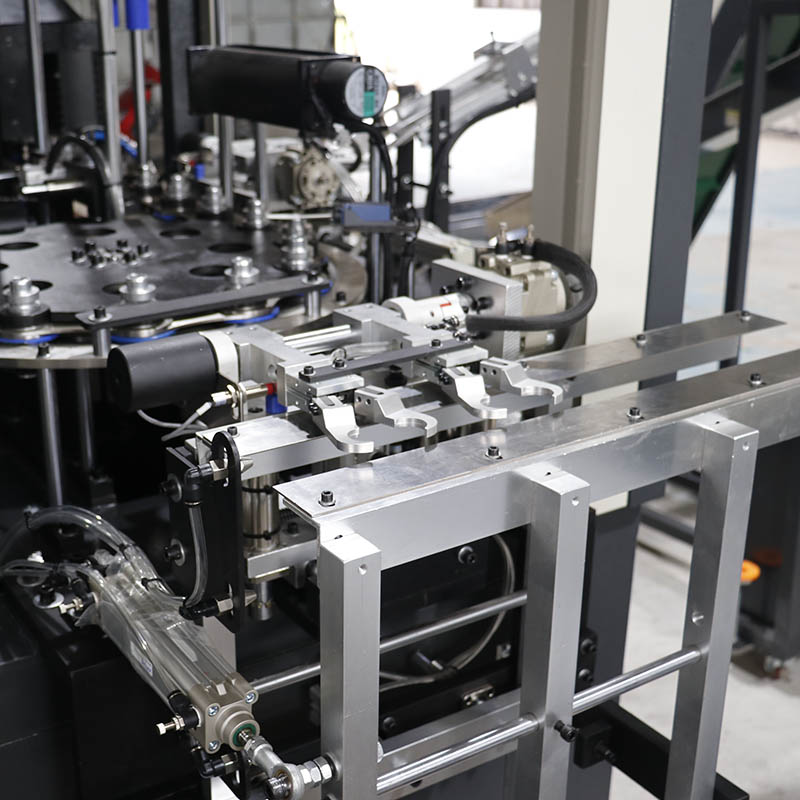

Lights-Out Manufacturing: These facilities are highly automated, with robotic systems handling everything from preform loading to placing finished bottles on pallets. This allows for continuous 24/7 operation with minimal human intervention, drastically reducing labor costs and maximizing asset utilization.

High-Speed, Multi-Cavity Production: Modern blow molding machines are equipped with multiple cavities (e.g., 8, 16, 32, or more). This means a single machine cycle produces multiple bottles simultaneously, achieving staggering outputs of tens of thousands of bottles per hour.

Integrated Production Lines: Efficiency is further amplified by seamless integration. Automatic conveyors link blow molders to downstream equipment like leak testers, labelers, vision inspection systems, and packing stations, creating a smooth, continuous flow that eliminates bottlenecks.

Energy and Material Optimization: Advanced process control systems meticulously manage energy consumption of ovens and compressors. Precise control over every gram of plastic ensures each bottle meets its spec with zero excess, leading to significant material savings, especially at high volumes.

2. Surgical Precision: Guaranteeing Flawless Quality

Consistency is king in packaging. A single defective bottle can halt a filling line or damage a brand's reputation. Fully automatic plants eliminate this variability.

Process Control and Repeatability: Every parameter—from preform heating temperature and infrared oven profile to stretch rod speed and blow pressure—is digitally controlled and monitored. This ensures that every single bottle, from the first to the millionth, is virtually identical.

Rigorous In-Line Quality Control: Sophisticated vision systems and sensors inspect 100% of production. They check for critical defects like pin-holes, wall thickness variations, ovalized necks, and contamination in real-time, automatically rejecting any non-conforming bottles.

Data-Driven Manufacturing: Modern plants are data hubs. Every aspect of the process is logged and analyzed. This allows for predictive maintenance (preventing downtime), detailed traceability (crucial for food and pharmaceutical clients), and continuous process improvement based on real-world data.

3. Boundless Innovation: Beyond the Standard Bottle

The capabilities of a fully automatic plant extend far beyond producing simple water bottles. They are the birthplaces of packaging innovation.

Lightweighting and Sustainability: Through advanced design and process engineering, plants can produce bottles that use significantly less plastic without compromising strength or functionality. This reduces material costs and environmental footprint, a key demand from today's consumers.

Advanced Material Handling: Plants expertly process a wide range of materials, including rPET (recycled PET) , helping brands meet their sustainability goals. They can also handle advanced barrier technologies and co-polyesters for specialized applications.

Complex and Ergonomic Designs: Whether it's a unique paneled shape for brand distinction, an integrated handle for easy carrying, or a custom closure system, modern molds and precise process control can reliably produce complex and innovative designs that were once impossible or too costly.

Integrated Services: Leading plants offer more than just blowing bottles. They provide full-turnkey solutions including package design, mold engineering, prototyping, and logistics support, acting as a true extension of their clients' teams.

Conclusion: The Strategic Advantage

Partnering with a state-of-the-art, fully automatic blow molding plant is not a simple procurement decision; it is a strategic move. It provides brands with a critical competitive advantage through:

Speed to Market: Rapid production and scalability allow for quick launches and adaptations.

Uncompromising Quality and Brand Protection: Eliminates the risk of packaging failure.

Cost-Effectiveness: Drives down the total cost per unit through superior efficiency.

Sustainability Credentials: Enables the use of recycled content and lightweight designs.