How Production Volume Dictates Your Choice of Blow Molding Machine

In the world of manufacturing, the choice of equipment is rarely about finding the "best" technology in absolute terms, but rather about finding the most appropriate technology for a specific business reality. Nowhere is this truer than in the selection of a blow molding machine for producing PET bottles. While factors like bottle design, budget, and available space all play a role, the single most decisive factor is production volume, or output.

Selecting a machine mismatched to your output needs can be a catastrophic financial mistake. An oversized fully automatic machine will drain capital for no reason, while an undersized semi-automatic machine will cripple your growth and profitability. This guide explains how to align your output requirements with the correct class of machinery.

The Two Worlds of Blow Molding

First, it's essential to understand the fundamental divide:

Semi-Automatic Machines: Require significant manual intervention for loading preforms and unloading finished bottles. The blowing process itself is automated.

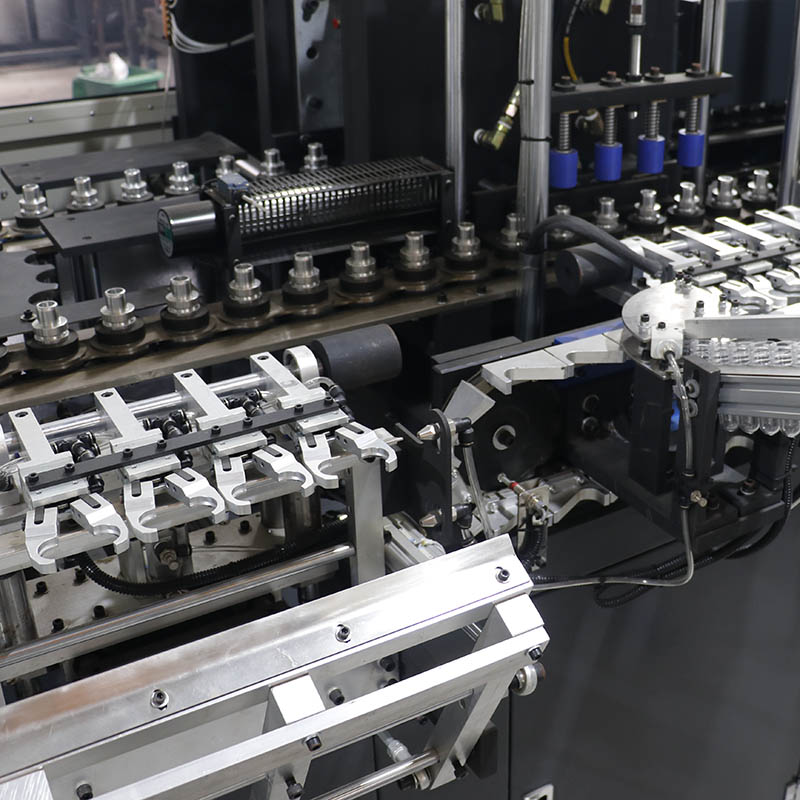

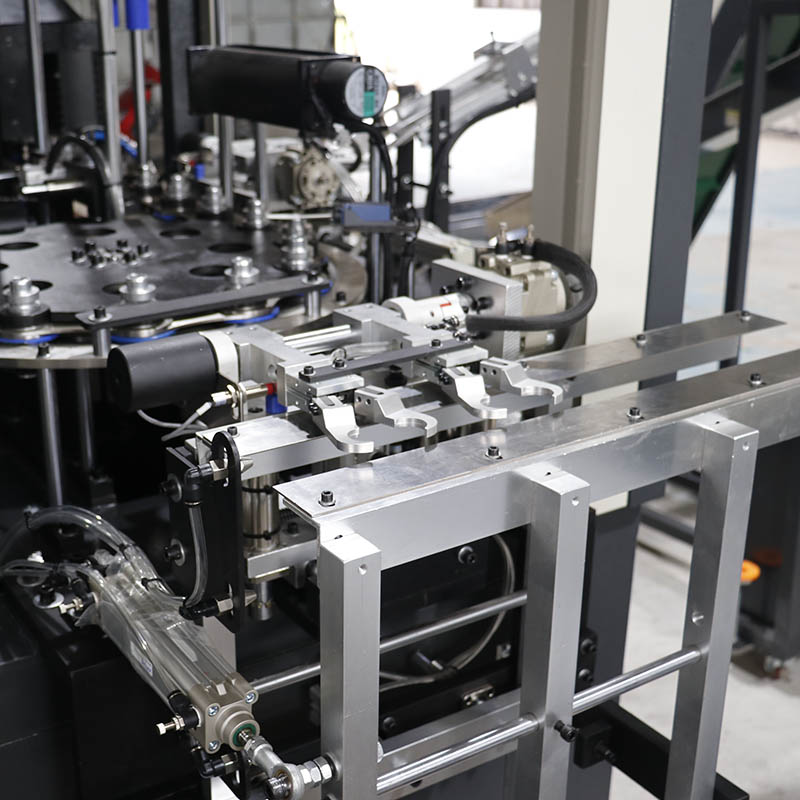

Fully Automatic Machines: Are integrated, robotic systems that automatically handle the entire process from preform loading to ejecting finished bottles onto a conveyor, requiring minimal human supervision.

The Output Spectrum: Making the Right Choice

Your target annual or monthly production volume will naturally lead you to the optimal machine type.

1. The Low-Volume Niche ( prototypes, and Specialty Products)

Output: Up to 500,000 bottles per month.

Recommended Machine Type: Semi-Automatic or Single-Station Automatic.

Why? At this volume, the primary concerns are flexibility and low capital investment.

Flexibility: A semi-automatic machine allows you to switch between different bottle designs and preforms in minutes. This is ideal for producing short runs of custom bottles, seasonal products, or conducting R&D prototypes without costly downtime for changeovers.

Cost: The upfront cost of a semi-automatic machine is a fraction of a full-scale automatic line. This preserves capital for other business needs and keeps the financial risk low.

Reality Check: While labor costs are higher per bottle, the absolute labor cost at this low volume is manageable and is easily outweighed by the savings in machinery cost and the value of flexibility.

2. The Medium-Volume Range ( Growing Brands and Contract Packaging)

Output: 500,000 to 5 million bottles per month.

Recommended Machine Type: High-Speed, Multi-Cavity Fully Automatic Lines or Multiple Semi-Automatic Machines.

The Strategic Crossroads: This is the most critical decision zone. The choice here defines your business model.

Path A: Choose Fully Automatic. If you have a stable, high-demand product (e.g., your own brand of water or juice), a single fully automatic line (e.g., 8-16 cavities) will be the most efficient. It slashes labor costs per bottle and ensures consistent, high-quality output. The higher initial investment is justified by lower operating costs.

Path B: Choose Multiple Semi-Automatics. If your business is contract packaging with a wide variety of clients and bottle shapes, multiple semi-automatic machines might be smarter. This setup allows you to run several different jobs simultaneously on different machines, providing unparalleled flexibility that a single automatic line cannot match.

3. The High-Volume Realm ( Large-Scale Beverage and FMCG Production)

Output: 5 million+ bottles per month.

Recommended Machine Type: High-Speed, Multi-Cavity Fully Automatic Lines.

Why? There is no debate here. At this scale, efficiency is everything.

Economies of Scale: The colossal output of a modern automatic line (capable of 40,000+ bottles per hour) drives the cost per bottle down to an absolute minimum. This is essential in the low-margin, high-volume beverage industry.

Labor Cost: The fully automated process means one operator can supervise multiple lines. The labor cost per bottle becomes negligible.

Consistency and Integration: These lines are integrated with automatic preform dehumidifiers, conveyors, fillers, and labelers, creating a seamless production "highway" that operates 24/7 with minimal variation in bottle quality.