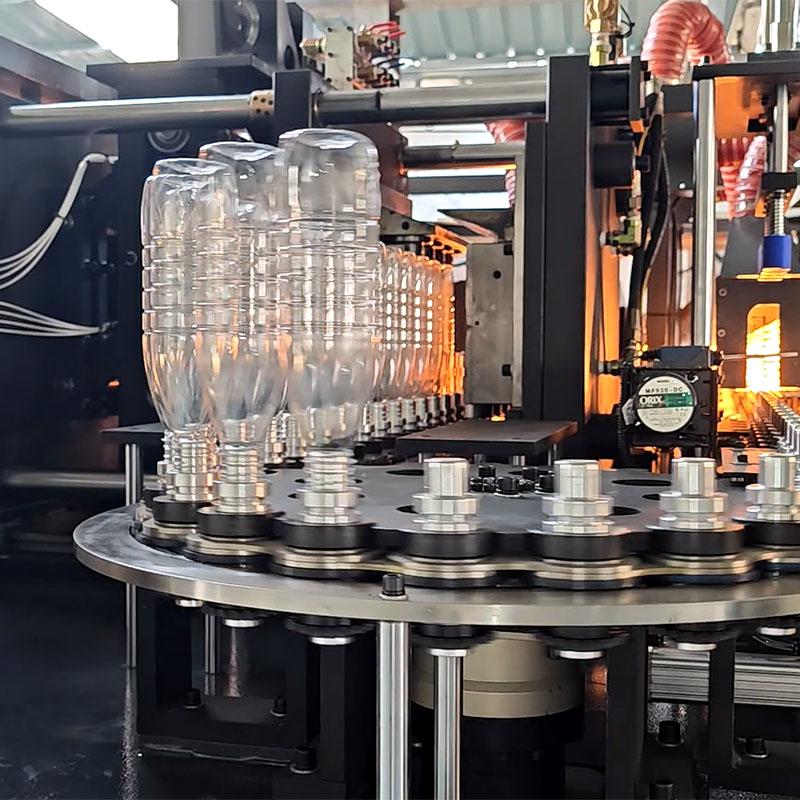

Energy-saving king! The fully automatic 4-cavity blow molding machine uses 35% less energy than traditional models. Actual test comparison!

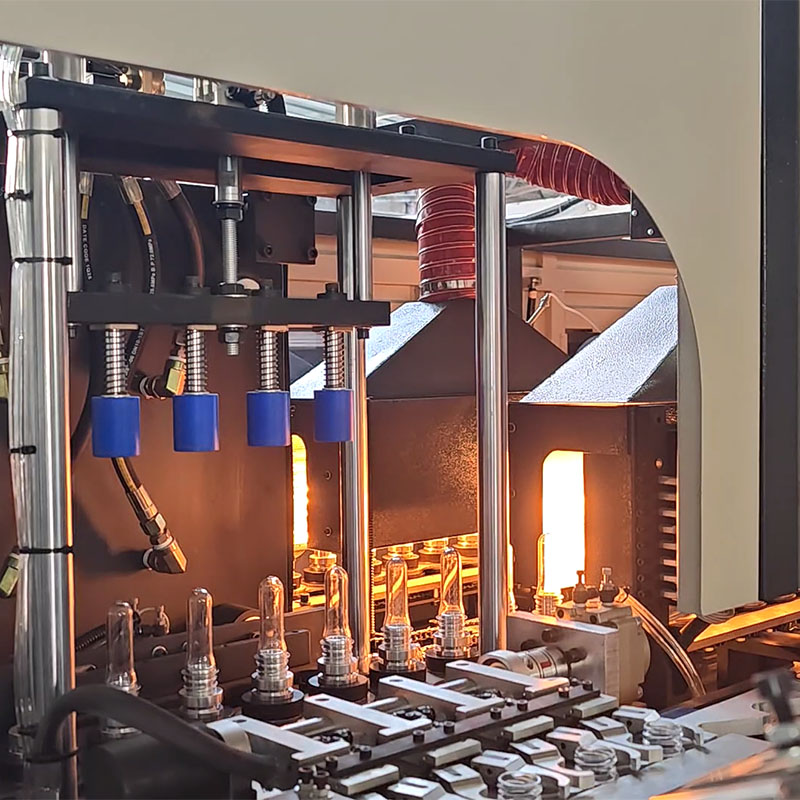

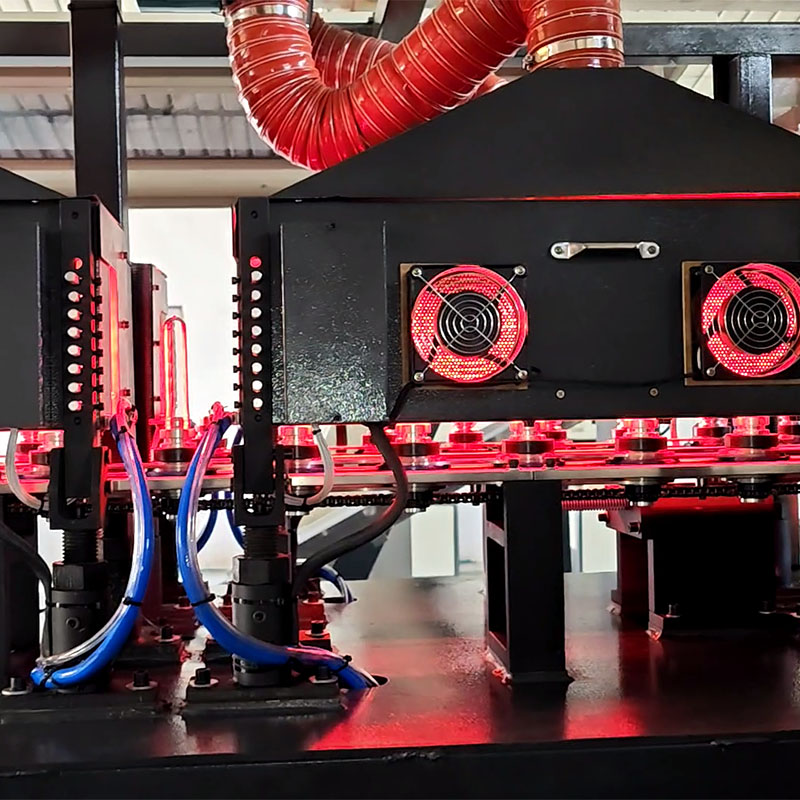

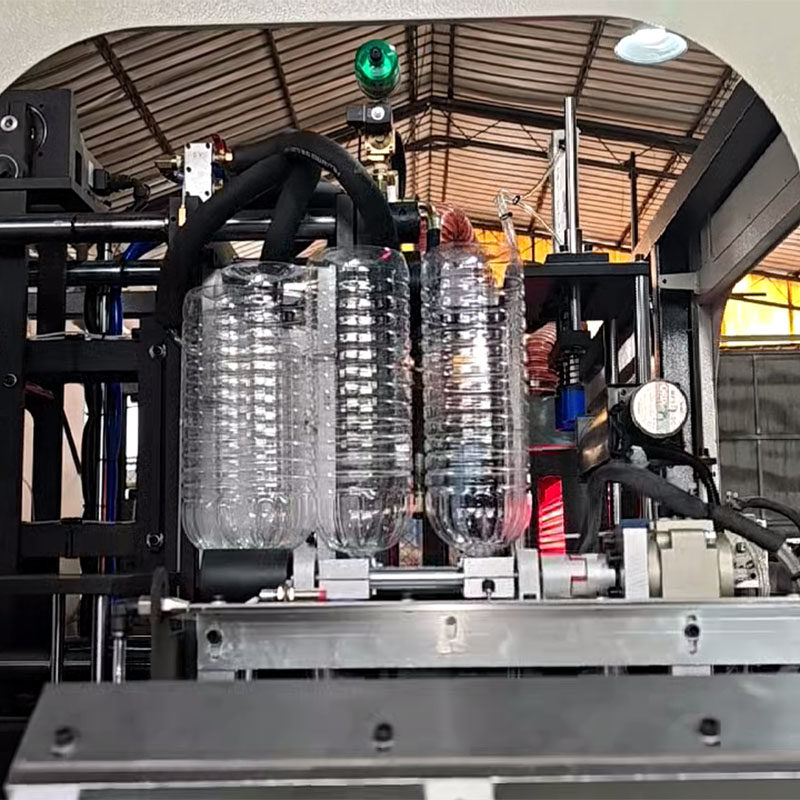

Using actual meter data, the video demonstrates how the equipment optimizes heating energy consumption (infrared energy-saving lamps) and the power system (servo motors recover kinetic energy). A case study shows that a water plant saved over 150,000 yuan in annual electricity costs, shortening the payback period to 1.5 years. The video also features engineers explaining the energy-saving technology details, reinforcing the cost-effectiveness selling point.